- Home

- About

- Services

- Gallery

- Contact us

- Blogs

- Residential House Construction Made Easy by Sri Guru Raghavendra Constructions

- Best Construction Solutions in Bangalore: Sri Guru Raghavendra Constructions

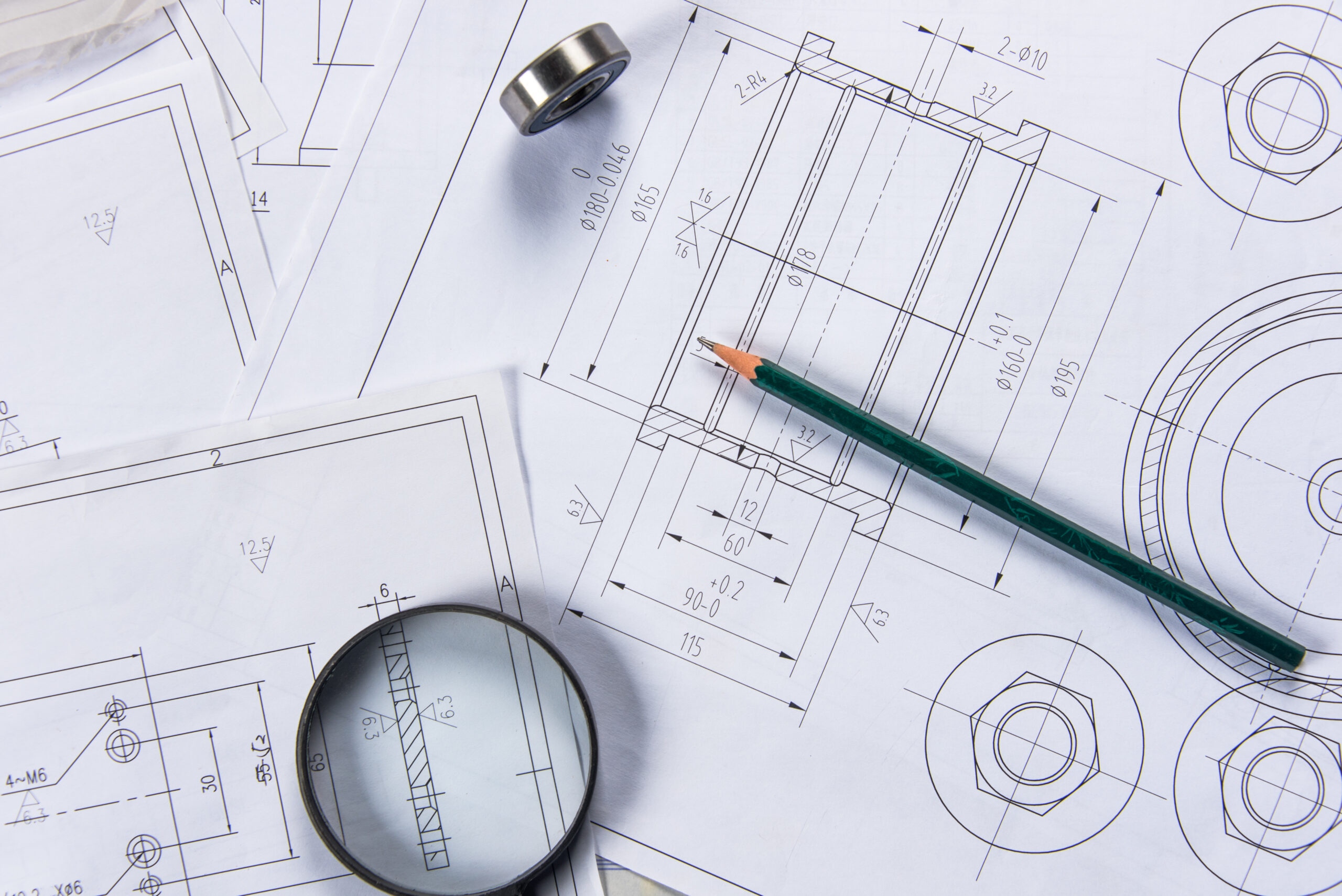

- Structural Drawing Tips by Sri Guru Raghavendra Constructions

- Why Choose Sri Guru Raghavendra Constructions for Your Commercial Project

- Top Benefits of Choosing Sri Guru Raghavendra Constructions for Commercial Projects

- The Best Commercial Builder in Bangalore: Sri Guru Raghavendra Constructions

- The Complete 2025 Guide to Commercial Construction: Build Your Vision in Bangalore

- Your Guide to Residential Construction in Bangalore | Sri Guru Raghavendra Construction

- The Ultimate Guide: 7 Essential Steps in Villa Construction

- The Ultimate Guide to Residential Interior Design by Sri Guru Raghavendra Construction, Bangalore

- 7 Essential Aspects of Remarkable Commercial Interior Design in Bangalore

- The Definitive Guide to Stunning Villa Interior Design: 10 Secrets for Your Bangalore Dream Home

- Easy Guide: Knowing How Much It Costs to Build Your Home in Bangalore in 2025

- The Ultimate Guide to Flawless Residential Construction in Bangalore: 5 Key Phases

- 10 Brilliant & Budget-Savvy Commercial Interior Design Secrets for Bangalore Businesses

- Unlock Your Dream Workspace: The Expert Guide to Finding the Perfect Office Interior Designer in Bangalore

- Your Ultimate Guide: Finding Top Interior Designers in Bangalore for a Stunning Space

- The Ultimate Guide to Office Interior Designers in Bangalore: Crafting Your Ideal Workspace

- The Ultimate Guide to Home Interior Design in Bangalore: Unlocking Your Dream Space

- Building Dreams: Your Ultimate Guide to House Construction in Bangalore

- Smart Savings: Unlocking 600 Sq Ft House Construction Cost in Bangalore (2025 Guide)

- Bangalore House Construction Cost Calculator: Your Ultimate Guide (2025)

- Navigating Construction Contracts in Bangalore: What Homeowners Need to Know

- Builders in Bangalore: The Definitive Homeowner’s Guide to Top Residential Construction Companies & Property Developers in 2025

- Best Affordable Interior Designers Bangalore 2025: Your Budget Home Guide

- Crafting Your Dream Space: Top Home Interior Designers in Bangalore for Every Style

- Elevate Your View: Modern Luxury Interior Design for Penthouses in Bangalore

- Transform Your Space: Find the Best Living Room Designer in Bangalore for Modern Homes

- Building Your Dream Home: A Complete Guide to Residential Construction in Bangalore for Homeowners

Useful Link

Contact

Structural Drawing Tips by Sri Guru Raghavendra Constructions

Introduction to Structural Drawings: Importance and Key Components

Structural drawings are indispensable in the construction industry as they serve as detailed blueprints for the planning and execution of building projects. These technical drawings are prepared by structural engineers and architects to convey precise information about the design, materials, and dimensions required for the structural integrity of a project. Their importance lies in ensuring safety, accuracy, and compliance with construction standards, as well as providing clear guidelines to builders and contractors.

Importance of Structural Drawings

- Safety Assurance: Structural drawings minimize risks by defining load-bearing capacities, reinforcement details, and material properties, ensuring the building can withstand anticipated forces.

- Clear Communication: They act as a common language between engineers, architects, fabricators, and construction teams, reducing misinterpretation and errors.

- Regulatory Compliance: These drawings ensure adherence to statutory codes, guidelines, and zoning regulations mandated by local authorities.

- Efficiency in Execution: Precise detailing in structural drawings streamlines the construction process, thereby saving both time and resources.

- Future Modifications: Well-drafted structural drawings are a valuable reference for maintenance, renovations, or extensions over the building’s lifespan.

Key Components of Structural Drawings

Structural drawings include various essential elements that collectively provide comprehensive guidance:

- Foundation Plans

- Details regarding foundation depth, type (e.g., rafts, piles), and reinforcement schedules.

- Load distribution data to define the interaction between the structure and ground.

- Framing Layouts

- Clearly demonstrate the arrangement of beams, columns, slabs, and trusses.

- Include details like spacing, alignment, and material specifications of structural members.

- Reinforcement Details

- Specify the placement, quantity, and diameter of rebars and other reinforcements.

- Include bending schedules and anchoring requirements.

- Load Calculations

- Provide allowable loads for dead, live, wind, and seismic forces.

- Document force distribution diagrams and stress analysis.

- Sectional Views and Elevations

- Depict vertical and horizontal cuts of different structural parts for enhanced clarity.

- Highlight specific construction layers, textures, and finishes.

- Material Details

- List the type, grade, and mix of concrete, steel, and other construction materials.

- Ensure the compatibility and durability of materials used.

Structural drawings form the backbone of any construction project, enabling professionals to execute designs with precision and foresight. Proper understanding and utilization of these documents safeguard the structural integrity of buildings and ensure the success of engineering endeavors.

Understanding Building Codes and Standards in Structural Design

Building codes and standards are essential components of structural design, providing comprehensive guidelines to ensure safety, durability, and compliance in construction. Architects, engineers, and construction professionals must have a thorough understanding of these regulations, as they shape the integrity of structures and safeguard occupants. Structural design revolves around codes that account for regional and environmental factors, material performance, load-bearing capacities, and permissible design practices. These regulations are typically developed by governmental and professional organizations and are periodically updated to reflect advances in technology and knowledge. By adhering to codes like the International Building Code (IBC) or region-specific standards, designers uphold critical safety measures and legal requirements. Building codes establish minimum acceptable levels for construction practices. They encompass various aspects such as fire resistance, structural stability, energy efficiency, and accessibility. For structural engineers, the focus often falls on ensuring stability and reliability under diverse conditions, including seismic activity, wind loads, or other external forces. Standards further define how materials such as steel, concrete, and wood must be applied and tested in construction processes. Incorporating codes into engineering drawings entails detailed documentation. Construction professionals must ensure that design calculations align with governing standards. Key elements such as beam sizes, reinforcement details, and foundation specifications should be presented explicitly, demonstrating compliance to stakeholders and inspectors.

Understanding these codes rests on effective collaboration between teams. Engineers, architects, and contractors must communicate to confirm compliance throughout project phases. This joint effort secures approval processes, reduces the risk of penalties, and guarantees a safe end product. Neglecting building codes can result in structural failures, higher costs due to retrofitting, and legal repercussions. Therefore, familiarity with applicable standards is a fundamental responsibility in structural design.

Tips for Accurate Dimensioning in Structural Drawings

Accurate dimensioning is a critical aspect of structural drawings as it ensures seamless construction and minimizes errors during implementation. Structural drawings need to be precise, clear, and standardized to effectively communicate design requirements to all stakeholders, including engineers, contractors, and fabricators.

Importance of Reference Points

Using proper reference points is essential. Dimension lines should begin from fixed, easily identifiable points such as grids, columns, or walls. These references provide clarity and consistency and help avoid ambiguity during execution. Every dimension noted should align with these reference points for interoperability across teams.

Consistency in Dimension Placement

Maintaining uniform spacing and arrangement for dimension lines can improve readability. Vertical and horizontal dimension lines should be systematically organized without unnecessary overlaps. Dimensional annotations must be placed with enough spacing to avoid confusion and allow for unambiguous interpretation.

Use of Standard Units

Standard units of measurement, such as millimeters or inches, should consistently be applied throughout the drawing. The units chosen must align with project specifications and regional practices to prevent miscommunication. Conversion between units should always be verified before finalizing the drawing.

Clear Labeling and Annotations

Important features such as centers of openings, cut-outs, and connection points should be distinctly labeled. Every dimension must be accompanied by notations when necessary, especially for intricate designs. Specialized symbols or abbreviations should follow conventions recognized in structural engineering.

Avoid Over-Dimensioning

Excessive dimensions can clutter the drawing, leading to potential misinterpretation. Structural drawings should include only the necessary dimensions required for construction and fabrication. Verification steps should be taken to ensure all critical elements are specified without redundancy.

Coordination with Other Design Elements

It is vital to coordinate dimensions with other design elements such as architectural and mechanical drawings. Every dimension in the structural drawing must correspond with broader design components to avoid clashes in execution.

Tools for Accuracy

Utilizing software designed for structural drawings can enhance accuracy and efficiency. Advanced design tools allow for automatic dimensioning, error detection, and adherence to industry standards. These tools also facilitate three-dimensional visualizations to verify dimensions comprehensively.

Ultimately, thoughtful and accurate dimensioning integrates structural integrity with practical implementation, making it central to the success of any construction project.

Using Proper Line Types and Symbols for Enhanced Clarity

Structural drawings serve as an essential communication tool in construction projects, and using appropriate line types and symbols is crucial to convey detailed information effectively. The clarity of these drawings significantly impacts the accuracy and quality of construction work. Ensuring consistency and standardization in line types and symbols assists professionals in interpreting the designs without ambiguity.

Line Types

Structural drawings differentiate elements like beams, columns, and reinforcement using distinct line types. Commonly used line types include:

- Continuous lines: Represent visible edges, structural components, and concrete outlines.

- Dashed lines: Indicate hidden edges or features that are not visible from the perspective shown.

- Dotted lines: Often depict objects or elements that are overhead or beneath the drawing’s plane of view.

- Centerlines: Mark central axes for symmetric components or elements.

By maintaining consistency with these line types, drafters ensure readability and provide precise visual cues to workers.

Symbols

Standardized symbols play an equally important role in structural drawings. These symbols simplify complex concepts, saving space while ensuring clarity. Common categories include:

- Reinforcement and steel symbols (e.g., bars, stirrups, and hooks).

- Footing symbols for foundations, including square and isolated footings.

- Concrete strength labels (e.g., C20, C25) that denote material quality.

- Directional indicators such as north arrows to orient the drawing.

Each symbol must adhere to industry standards and be appropriately labeled within the legend section of the drawing.

Enhanced Clarity Through Consistency

To improve clarity, structural drawings should adopt globally recognized standards, such as those provided by the International Organization for Standardization (ISO). Additionally, drafters should use annotations, legends, and dimension lines to supplement the information conveyed through line types and symbols.

Accurate representation ensures that contractors, engineers, and fabricators can execute the project with precision, minimizing errors and delays. Clear and concise drawings foster seamless collaboration among all stakeholders.

Incorporating Load Calculations and Safety Factors

Accurate load calculations are fundamental in structural drawings to ensure that the designs can withstand operational stresses, environmental forces, and unforeseen influences. Structural engineers at Sri Guru Raghavendra Constructions emphasize the importance of understanding the types of loads a structure may encounter, such as dead loads, live loads, wind loads, seismic loads, and impact loads. Each load type must be thoroughly analyzed to determine its effect on the integrity of the design.

To calculate loads effectively, engineers utilize established formulas and design codes, such as those provided by local building standards or international guidelines. This process requires understanding material properties, including their strength, durability, and elasticity. For instance, concrete and steel, often used in construction projects, have distinct load-bearing capacities and require careful consideration in the calculations. Engineers also account for factors like load redistribution, lateral forces, and point loads to ensure comprehensive assessments.

Safety factors are integral to structural planning and are incorporated to account for uncertainties in load assumptions, construction practices, and material performance. While industry standards provide specific ranges for safety factors, choosing the most appropriate factor involves professional judgment and project-specific conditions. A higher safety factor might be used for structures exposed to severe environmental conditions, while standard ranges may suffice for routine applications.

The inclusion of safety factors ensures that the structure can handle unexpected conditions, such as overloads or material degradation over time. Regular communication between engineers, designers, and construction teams strengthens this aspect, as multidisciplinary collaboration can identify potential risks early in the design phase. Proper documentation in structural drawings highlights the calculated loads and applied safety factors clearly, enabling seamless review and approval processes across governing bodies.

Through meticulous load calculations and adherence to safety factors, engineers can confidently design structures that meet functional requirements while maintaining optimal safety and reliability.

Best Practices for Detailing Connection Points and Joints

Properly detailing connection points and joints in structural drawings is essential to ensure stability, safety, and ease of construction. These areas are often the focus of high stress and require precise attention to avoid failure. Structural engineers must craft these details carefully, keeping readability and accuracy as core principles.

- Understand Load Path and Stress Distribution

- Every joint or connection point transfers loads throughout the structure. It is critical to understand how forces are distributed to prevent undue stress on any single component.

- Detailing must include specifications for reinforcements, such as bolts, welds, or rebar, tailored to the connection type and expected loads.

- Use Standardized Joint Types

- Standardized connection types—like pinned, fixed, and hinged—help maintain consistency and simplicity during construction.

- Selecting appropriate joint types ensures the structure behaves as intended, whether allowing rotation in steel frames or resisting movement in concrete structures.

- Ensure Clarity in Linework and Annotation

- Connection details should be illustrated with sharp, clear linework to delineate boundaries and specifications. Avoid overcrowding with excessive notes or dimensions.

- Annotated diagrams must include material specs, bolt/weld details, spacing, and dimensions to assist builders and inspectors.

- Incorporate Design Codes and Standards

- Adherence to local and international building codes, such as AISC (American Institute of Steel Construction) or Eurocode, ensures all connection details meet legal and engineering requirements.

- Design codes provide pre-established guidelines for loading, connections, and safety measures.

- Account for Construction Tolerances

- Drawings should include allowances for construction tolerances to mitigate inaccuracies during fabrication and assembly. This prevents misalignments from causing system-wide instability.

- Dimensioning must consider joint flexibility, thermal expansion, and wear over time.

- Use Computer-Aided Software for Precision

- Employ structural engineering software (e.g., AutoCAD, Tekla Structures) to generate high-accuracy drawings that simulate joint behavior under various conditions.

- Updated digital models allow for easy revisions and seamless collaboration across design teams.

- Prioritize Inspections and Cross-Checking

- All joint details should undergo a thorough review by structural engineers to validate their accuracy and compliance.

- Inspections should also evaluate their feasibility for practical execution during construction phases.

Ensuring Proper Reinforcement Placement in Concrete Structures

Proper reinforcement placement is critical for the safety, durability, and overall performance of concrete structures. Accurate positioning and alignment of reinforcing steel enhance the structural integrity, resist applied loads, and ensure compliance with design specifications.

Key Guidelines for Reinforcement Placement

- Adherence to Design Specifications: Structural drawings provide precise details, including bar sizes, spacing, and placement locations. Contractors must follow these specifications rigorously to avoid deviations that could weaken the structure.

- Clear Cover Maintenance: Ensure the concrete cover around the reinforcement adheres to the specified dimensions. Adequate cover protects steel from corrosion and contributes to fire-resistance properties. Spacers and chairs can maintain uniform cover thickness.

- Proper Bar Alignment: Reinforcing bars must remain straight and securely fastened to prevent movement during concrete pouring. Misalignment can lead to non-uniform stress distribution and compromise loading capacity.

- Use of Binding Wire: Steel bars should be tied firmly using binding wire at intersections. This practice minimizes displacement during construction activities and ensures the correct configuration post-pouring.

- Overlaps and Lapping Length: Reinforcement overlaps must follow the recommended lapping length as specified in the drawings. Overlapping is essential for transferring stress between bars when longer lengths are unavailable.

Vital Checks During Placement

- Inspection Before Pouring: Engineers should inspect reinforcement placement to verify alignment, spacing, and conformity with the design.

- Avoid Congestion: Proper spacing prevents congestion, which can lead to insufficient concrete flow and poor bonding around the steel bars.

- Placement of Stirrups and Anchoring Bars: Usability of stirrups, hooks, and anchoring bars must be ensured for structural design requirements such as shear strength.

Investing time and effort in ensuring precise reinforcement placement contributes to the long-term performance and sustainability of concrete structures. Every aspect of this process must align with approved engineering designs and industry standards.

Leveraging Modern Software Tools for Structural Drawing Precision

The evolution of technology has profoundly impacted the field of structural design, introducing advanced software tools that enhance precision, efficiency, and collaboration. Sri Guru Raghavendra Constructions recognizes the importance of leveraging these tools to ensure the highest quality in structural drawings. Modern software solutions are integral to achieving accuracy and meeting project requirements.

Structural drawing software such as AutoCAD, Revit, and Tekla Structures provides engineers and designers with powerful tools to create dimensionally accurate and meticulously detailed models. These platforms enable professionals to visualize projects in three dimensions, allowing for a clearer understanding of layouts and component relationships. With built-in functions for automatic error detection, designers can identify inconsistencies early in the planning process, reducing costly corrections during construction.

Key Advantages of Modern Software Tools:

- Enhanced Precision: Automated calculations and detailed modeling features minimize human errors. These tools are designed to ensure exact alignment, measurements, and material specifications.

- Improved Collaboration: Cloud-based platforms facilitate real-time sharing and updates between teams, ensuring seamless coordination among architects, engineers, and construction professionals.

- Time Efficiency: Predefined templates and intelligent components allow for faster creation and modification of drawings, significantly reducing project timelines.

- Simulation and Analysis: Structural drawing software often incorporates analysis capabilities, permitting users to simulate stress tests, load distributions, and environmental factors directly within the design phase.

Transitioning fully to modern digital platforms also allows organizations to embrace Building Information Modeling (BIM) practices. BIM software tools integrate design and construction details into one cohesive workflow, making it easier to maintain consistency and predict outcomes throughout a building’s lifecycle.

Sri Guru Raghavendra Constructions advocates for continued training and adoption of modern software technologies to keep pace with industry advancements. By maximizing the utility of contemporary tools, structural drawings become more refined, paving the way for well-engineered and enduring construction projects.

Common Mistakes to Avoid in Structural Drawings

Structural drawings are fundamental to the design and construction process, serving as a blueprint for engineers, architects, and contractors. Errors can lead to significant delays, increased costs, and even compromised safety. Recognizing and avoiding common mistakes is crucial for maintaining precision and efficiency.

- Omitting Key Details

Incomplete documentation is a recurring issue in structural drawings. Failing to include essential dimensions, material specifications, reinforcement details, or load calculations can result in confusion during construction. Every element should be meticulously documented to ensure alignment across all teams involved.

- Misinterpretation of Design Intent

Miscommunication between designers and drafters can lead to inaccuracies in the representation of the structural design. Ambiguities in notes, unclear annotations, or improper use of symbols can misrepresent the intended design, leading to potential errors in the construction phase.

- Inaccurate Placement of Columns and Beams

Improper alignment of structural elements such as columns and beams is a critical error often found in drawings. If these components are not positioned as per the load distribution plan, it can weaken the structural integrity of the building.

- Neglecting Cross-Referencing Between Different Drawings

Structural drawings are typically accompanied by architectural, electrical, and plumbing plans. Failing to cross-reference these drawings can result in design conflicts, such as a structural column interfering with a plumbing route or electrical conduit.

- Overlooking Local Codes and Standards

Disregarding building codes or standards relative to the project’s location can lead to non-compliance, penalties, and compromised safety. Drawings need to strictly follow the prescribed regulations, from material specifications to seismic criteria.

- Poor Dimensioning Practices

Incorrect or inconsistent dimensioning can create confusion during construction. Dimensions should be clearly labeled, appropriately scaled, and standardized across all sheets to avoid misinterpretation or measurement discrepancies.

- Lack of Revision and Review

Failure to review drawings after iterative design changes can introduce discrepancies or outdated information. Detailed checks and peer reviews must be conducted to eliminate errors before final approval.

- Unclear Notations and Legends

Ambiguous notations or missing legend details can create obstacles for construction teams. All abbreviations, symbols, and technical terms used in the drawing should be defined clearly to enhance understanding.

- Ignoring Load Paths

Ignoring or improperly detailing load paths can lead to structural failures. The drawings must illustrate precise routes for loads to transfer from beams to columns and down to the foundation.

- Underestimating Tolerances

Structural drawings that disregard acceptable tolerances for material size, clear spacing, and connections can lead to fabrication issues and increased costs during construction. Tolerances should always be well-defined and achievable.

By addressing these frequent mistakes, professionals can create structural drawings that are accurate, reliable, and practical, ensuring that the construction process proceeds seamlessly and on schedule.

Collaboration Techniques Between Engineers and Architects

Effective collaboration between engineers and architects is vital for the success of any construction project. By harmonizing technical expertise with creative vision, both parties can ensure the functionality, safety, and aesthetic appeal of structures. To achieve this synergy, several strategies and processes can be implemented.

- Establishing Clear Communication Channels

- Both engineers and architects should partake in regular meetings to discuss project goals, potential challenges, and updates to ensure smooth coordination.

- Tools like Building Information Modeling (BIM) software can help both parties visualize designs and structural frameworks simultaneously, reducing misunderstandings.

- Maintaining detailed project documentation allows for timely reference and clarification when complexities arise.

- Shared Understanding of Roles

- Architects should have a basic understanding of structural limitations, enabling them to innovate without compromising safety.

- Engineers should be mindful of the architect’s vision for the project, balancing practicality with artistry to achieve optimal results.

- A mutual appreciation for each other’s expertise fosters respect and smoother collaborative efforts.

- Early Involvement and Integrated Workflow

- By involving engineers during the concept stage, potential structural constraints can be identified and addressed promptly, saving time and resources.

- Using integrated workflows, architects and engineers can synchronize their contributions to reduce rework and conflicts between design and execution plans.

- Conflict Resolution Strategies

- Disparities between engineering requirements and architectural vision should be resolved objectively by prioritizing the best interest of the project.

- Open dialogues and brainstorming sessions can help develop creative solutions that balance aesthetics with functionality.

- Technology Utilization

- Tools like 3D modeling and simulation software improve collaboration by providing accurate visual representations of designs and calculations.

- Cloud-based platforms enable seamless sharing of updates, revisions, and project schedules to keep both teams aligned.

By leveraging these collaboration techniques, engineers and architects can ensure that their respective skills contribute to structurally sound and visually appealing buildings.

Optimizing Structural Drawings for Construction Efficiency

Structural drawings play a pivotal role in ensuring the construction process is streamlined and error-free. By optimizing these drawings, professionals can reduce project delays, minimize material wastage, and enhance overall project efficiency. Sri Guru Raghavendra Constructions emphasizes the importance of precision in these deliverables to achieve flawless execution.

Achieving construction efficiency begins with clear communication through the drawings. Structural drawings should use standardized symbols and consistent annotations to avoid misinterpretation by project teams. Leveraging universally accepted formats ensures clarity across diverse stakeholders, such as architects, engineers, and contractors. This reduces the likelihood of miscommunication during implementation.

Incorporating detailed specifications ensures that all project requirements are met. These specifications include dimensions, materials, and connection details, which leave no room for ambiguity. Proper detailing facilitates accurate estimation of resources, reducing the risk of material shortages or excesses. Additionally, the inclusion of tolerances in design minimizes on-site adjustments and bolsters construction accuracy.

Modern technology has revolutionized the creation and optimization of structural drawings. Advanced software such as Building Information Modeling (BIM) allows for real-time collaboration and validation of construction data, helping detect errors prior to on-site work. The use of 3D modeling further enhances the ability to visualize complex designs, assisting in better planning and execution.

To withstand unforeseen circumstances during construction, structural drawings should incorporate contingency provisions. These may include reinforcement details for added strength or modular designs to facilitate adaptation. Sri Guru Raghavendra Constructions recommends prioritizing flexibility and resilience in designs to cater to dynamic project needs.

Professionals must also evaluate structural drawings through rigorous quality checks. This ensures compliance with safety regulations and eliminates discrepancies. Regular reviews and audits prevent costly rework and promote smooth construction workflows.

Optimized structural drawings pave the way for efficiency, ensuring projects are not only timely but also cost-effective.

Conclusion: The Role of Expert Structural Drawings in Project Success

Structural drawings serve as the foundation of any construction project, offering detailed insights into the layout, materials, measurements, and specifications of structural elements. Their accuracy and clarity are paramount in ensuring project success, as they enable precise execution by architects, engineers, contractors, and workers. An expertly crafted structural drawing can significantly reduce the likelihood of errors or misinterpretations during implementation, thus saving time, money, and resources. Expert structural drawings contribute to the seamless integration of various systems within a building, including electrical, plumbing, and HVAC systems. By clearly outlining dimensions, locations, and spatial relationships between each element, they ensure components are installed correctly without clashes or compromises. Moreover, these drawings provide stakeholders with a clear understanding of project requirements, facilitating collaboration and communication throughout the lifecycle of the construction. Risk mitigation is another key aspect of expert structural drawings. With detailed annotations and specifications, potential issues such as structural instability, overloading, or material incompatibility can be addressed before construction begins. This proactive approach minimizes unforeseen complications while maximizing safety—a critical factor for both workers and future occupants. Structural drawings are also indispensable tools in legal and regulatory compliance. They adhere to building codes, zoning laws, and other industry standards, streamlining approval processes and reducing delays. Their role extends to fostering sustainability by specifying efficient materials and environmentally-conscious practices, aligning projects with eco-friendly goals.

By providing a comprehensive roadmap, expert structural drawings empower teams to achieve precision, quality, and efficiency. Their importance cannot be overstated in delivering construction projects that meet expectations while adhering to budgetary and scheduling constraints. As such, they remain an essential vehicle driving structural integrity and project success.